News & Info

TERRATEC delivers a 3.85m diameter Rock Slurry TBM for Mumbai Sewage Disposal Project-Stage II, PST-1 in India.

TERRATEC is pleased to announce the delivery of a 3.85m Rock Slurry Machine for the Mumbai Sewage Disposal Project (MSDP) Stage-II – PST1 in Mumbai, India by J Kumar and Michigan Engineers Private Ltd. (MEPL) Joint Venture and the client Brihanmumbai Municipal Corporation (BMC).

TERRATEC is the sole supplier for Mumbai's sewerage segmental tunnels, providing two Tunnel Boring Machines (TBMs) for the project. These TBMs include a Rock Slurry TBM and a Rock EPB TBM, which will be used for the construction of the Mumbai Priority Sewer Tunnel (PST-1) spanning 5.8 kilometers and Priority Sewer Tunnel (PST-2) covering a distance of 4.7 kilometers.

The primary objective of the sewer tunnels in Mumbai is to improve the quality and reliability of wastewater collection, treatment, and disposal processes, while also minimizing the environmental impact caused by wastewater. These tunnels are designed to create a healthier and enhanced environment for the residents of Mumbai by implementing more efficient and sustainable wastewater management methods.

The TERRATEC Rock Slurry TBM is equipped with a Slurry System which controls the pressure in the excavation face by injecting slurry into the Cutter Chamber where the slurry is mixed with the excavated material. The mixture is pumped out of the tunnel to a separation and recirculation plant.

The machine is designed to handle various geological conditions along the tunnel alignments consisting of weathered/fresh breccia and basalt. The TBM has 23 rings of 15” replaceable disc cutters and a high-speed main drive which is capable of turning the cutter head at up to 8 revolutions per minute. The TBM is equipped with an active articulation system to accommodate a minimum curve radius of 250mR. The TBM's main drive is hydraulic due to size constraints and the installation of a shield integrated man lock.

The TBM is using 5+1 universal type segment design with reinforced concrete segments that are 200mm thick and 1200mm wide. Slurry removal and treatment is via the TERRATEC Slurry Transportation System and Slurry Treatment Plant.

The Slurry Transportation System efficiently manages the discharge of the slurry by utilizing a Centrifugal Slurry Pump. This system removes excavated ground spoils and cuttings by transporting them to the surface through a network of pipelines and hoses. Subsequently, the slurry is directed to the Slurry Treatment Plant, equipped with advanced mud treatment technology. Additionally, the plant features a remote-control maintenance system, enabling cost-effective long-distance excavation.

|

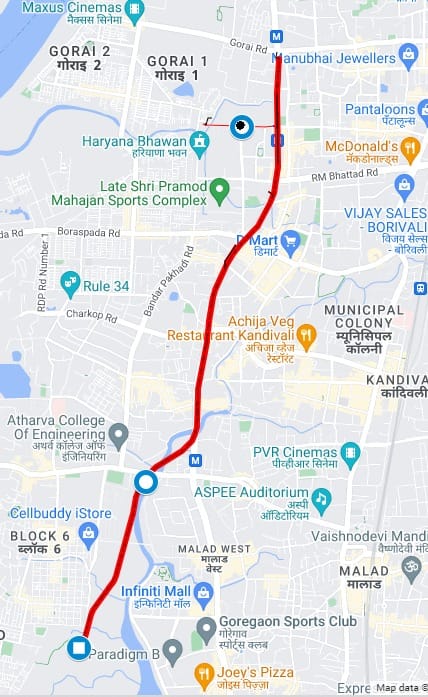

The MSDP – Stage II Priority Works project consists of several sections, a sewer tunnel along Link Road, extending from Don Bosco Junction to the existing Malad Pumping Station. Additionally, a branch sewer tunnel will connect from the Gorai Pumping Station and another sewer tunnel will run from the existing Malad Pumping Station to the proposed Malad IPS at Malad WwTF. The project also involves the construction of associated shafts and upstream connections. These infrastructure additions will effectively reduce the volume of wastewater flowing into the current collector sewer, enabling the decommissioning of the existing pumping stations located at Gorai, Shimpoli, Charkop, and Malad. |

|

The project encompasses various infrastructure components, including the expansion of sewage collection networks, construction of new pumping stations, establishment of wastewater treatment facilities and implementation of treated effluent disposal systems. Once operational, these treatment plants are expected to recycle a staggering 2,464 million litres of sewage per day. Apart from meeting the city's substantial water demand, these initiatives will significantly reduce water pollution levels and contribute to the rejuvenation of Mumbai's Mithi and Oshiwara rivers.

In another related development, the Mithi River Water Quality Improvement Tunnel project recently witnessed the successful deployment of the refurbished TERRATEC 3.14 EPB TBM. This machine, previously utilized for the completion of the Mumbai Sewer Disposal Project (MSDP) Stage-II Priority Works, achieved a breakthrough in mid-June under the joint venture of J Kumar Infraprojects and MEPL. The 3.14m EPB TBM demonstrated remarkable progress, with a monthly advancement of 370m, a commendable feat considering its size.

_

For more information visit: www.terratec.co

Media inquiries:

info@terratec.co / pr@terratec.co