News & Info

TERRATEC recently celebrated the successful completion of a 300m deep, 4.1m diameter, ventilation shaft at the Buriticá mine development project, in Colombia.

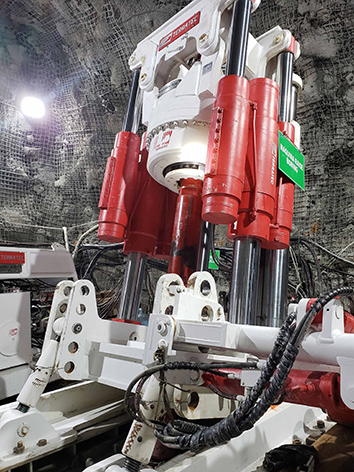

Peruvian mining contractor INCIMMET deployed a custom-built TR2000 Raise Boring Machine (RBM) to excavate the shaft in challenging ground conditions, putting this highly-robust machine through its paces during its first bore at the mine.

Located approximately two-hours northwest of Medellin, Colombia’s second-biggest city, Continental Gold’s flagship Buriticá mining complex is one of the world’s largest remaining untapped high-grade gold deposits, encompassing an area of about 75,000 hectares in the Antioquia Department. The mining complex, which is in the early stages of development, is Colombia’s first modern underground mine and was designated as a Project of National Strategic Interest (PINES) by the Colombian government, in November 2015.

|

Arguably the biggest challenge for the mine development project is the area’s geology. Ground conditions at the Buriticá complex largely consist of andesite-porphyry, diorites and monzodiorites with intrusive hydrothermal gaps within the volcanic and sedimentary sequences. These mixed and fractured conditions provided a challenge both to the integrity of the reamer and the capability of this robust machine. Mineralized gaps, which are frequently associated with the development and alteration of clay minerals, required constant monitoring of the excavation and appropriate advance rates to provide good progress in this difficult terrain. “Not all Raise Boring equipment is capable of working with such robustness in these conditions,” says TERRATEC Regional Raise Boring Operations Manager, John Alejos. “Without doubt, this changing terrain is almost impossible to drill at such depths and such diameters. Only a team as strong as this, with the technical support of our on-site staff, is able to carry out such a task successfully and not without difficulties.” |

Custom manufactured at TERRATEC’s workshop in Tasmania, Australia, the TR2000 Raise Boring Machine was designed for ease of operation and maintenance, while providing a high level of reliability. The unit is designed to “comfortably” execute raises of up to 500 meters at 2.4m diameter and larger ones up to 4.1m diameter (of shorter depths). It has a maximum pilot drilling torque of 42,000Nm, a reaming torque of up to 209,000Nm and breakout to 236,000Nm. The maximum down thrust force is 665kN with upthrust being 4,150kN. The total installed power on the machine is 360kW.

TERRATEC’s experienced Engineering and Field Service Team can assist buyers from the planning stage, including custom design specifications, assembly and operation of Raise Boring Machines on-site, and lifetime servicing and maintenance support.

TERRATEC has numerous Raise Boring Machines currently working along the American continent in Canada, USA, Mexico, Colombia, Peru and Argentina. These include the company’s entire range of vertical mining drilling equipment, including Raise Boring Machines, Down-Reaming Machines and Box Holing Rigs, as well as a combination of these in the form of Universal Boring Machines, all of which have been recognised worldwide for their high-performance and innovative design.

_

For more information visit: www.terratec.co

Media inquiries